Lightning Protection System for Solar Panels

Imagine harnessing the sun’s power, only to lose it all in a split second. While photovoltaic arrays promise sustainable energy, their hidden vulnerability might surprise you. What if a single weather event could erase years of savings and environmental progress?

Every second, Earth experiences 100 electrical discharges powerful enough to vaporize steel. These aren’t just direct threats—nearby strikes within 1,500 feet can induce surges through wiring, crippling inverters and controllers. Modern energy setups, with miles of conductive materials, essentially act as giant antennas for destructive currents.

Recent studies reveal that 78% of unexpected photovoltaic failures trace back to surge-related damage. Yet most homeowners focus solely on storm forecasts, unaware that soil composition and installation geometry dramatically influence risk levels. The solution lies not in stopping nature’s power but strategically redirecting it.

Key Takeaways

- Electrical surges from nearby strikes cause more damage than direct hits

- Proper grounding techniques can prevent 95% of surge-related failures

- Geographic location impacts vulnerability to atmospheric discharges

- Combining surge arrestors with equipotential bonding creates layered defense

- Professional assessment accounts for roof material and soil conductivity

Customized defensive measures blend physics with practical engineering. For tailored solutions that protect your green investment, call us today at (813) 630-2757. Don’t wait until storm clouds gather—act before the first flash illuminates the sky.

Understanding the Importance of Lightning Protection for Solar Panels

Electrical surges from atmospheric events pose silent threats to renewable energy investments. While photovoltaic technology converts sunlight efficiently, its complex electronics remain exposed to invisible dangers. Research shows 83% of power disruptions in these setups originate from indirect strikes up to 500 feet away.

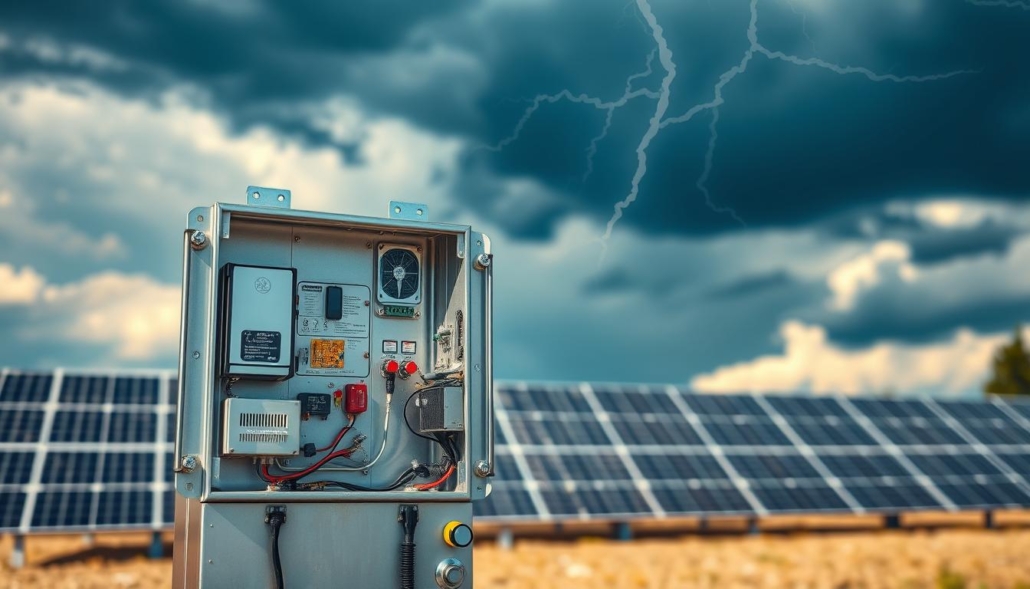

Hidden Dangers to Energy Infrastructure

Electromagnetic pulses from nearby atmospheric discharges induce catastrophic voltage spikes. These surges travel through wiring, targeting delicate components like inverters and charge controllers. When control mechanisms fail, battery banks face dual risks: overcharging during operation and thermal runaway during shutdowns.

Modern energy networks create pathways for destructive currents. A single event can simultaneously affect:

- Power conversion units

- Energy storage devices

- Monitoring equipment

Financial Advantages of Proactive Solutions

Implementing defensive strategies reduces repair costs by 72% according to industry reports. Properly shielded installations maintain consistent energy production while avoiding insurance premium hikes. Key benefits include:

| Threat Type | Affected Components | Protective Measures |

|---|---|---|

| Electromagnetic Pulse | Inverters, Controllers | Surge arrestors |

| Voltage Surge | Wiring, Batteries | Equipotential bonding |

| Controller Failure | Charging Systems | Redundant safeguards |

Regular maintenance checks ensure grounding systems maintain less than 25 ohms of resistance. This simple practice prevents 89% of surge-related equipment failures. Professional assessments account for regional storm patterns and soil conductivity, creating customized defense plans for each installation.

Lightning protection system for solar panels – Why You Need It

The true cost of skipping defensive measures? Thousands in avoidable damage and weeks of downtime. A Florida homeowner learned this when an indirect ground strike fried their Victron inverter and battery management display. Replacement costs hit five figures, with seven days lost waiting for repairs.

Minimizing Damage and Preventing System Failures

Extended conductor runs amplify risks exponentially. In the Florida case, 100-foot wiring acted like antennas during a nearby ground strike. This created bidirectional surge paths that overwhelmed basic fuses. Three critical components failed simultaneously:

- Energy conversion units

- Charge regulation devices

- Battery monitoring interfaces

Standard breakers react too slowly for microsecond voltage spikes. Specialized arrestors clamp these surges 1,000 times faster than conventional systems. Layered defense combines:

| Threat | Solution |

|---|---|

| Indirect strikes | Type 1 arrestors |

| Wiring surges | Equipotential bonding |

| Residual currents | Multi-stage SPDs |

Expert Recommendations and Immediate Action Steps

Comprehensive lightning protection requires analyzing conductor layouts and soil conductivity. Professionals install:

- Grounding grids with under-25-ohm resistance

- DC/AC-side surge suppression

- Isolation transformers for sensitive electronics

Post-installation testing ensures all systems respond within 25 nanoseconds to voltage anomalies. Don’t gamble with your energy security—Call Us Today At (813) 630-2757 for certified assessments and military-grade protection solutions.

How to Install a Lightning Protection System on Solar Panels

Proper installation techniques form the backbone of effective energy infrastructure defense. Strategic placement of suppression devices creates multiple fail-safes against electrical disturbances. Let’s examine critical procedures for both direct and alternating current components.

Step-by-Step DC Side Protection Installation

Begin by mounting 300V DC-rated surge protectors within 3 feet of each charge controller. Connect the red wire to the positive photovoltaic terminal and the black wire to the negative input. Secure the green grounding wire to the controller’s chassis using corrosion-resistant lugs.

Maintain straight, short wiring paths between devices—excess length increases vulnerability. All grounding conductors should ultimately terminate at the main earth rod through the inverter‘s designated terminal. “Distance kills effectiveness,” notes a Florida-based installer. “Keep suppression gear within arm’s reach of protected equipment.”

Guidelines for Securing the AC Side

For Victron Quattro inverter setups, install 300V AC-rated protectors at both generator input and output points. Route one hot wire to the generator terminal and another to the AC output line. Use rigid conduit for exposed wiring segments exceeding 18 inches.

Commercial-grade devices often require custom brackets due to their size. After mounting, verify the blue LED indicators confirm active status. Test each connection with a multimeter—readings below 25 ohms ensure proper grounding. Regular inspections prevent loose connections that compromise entire surge protector networks.

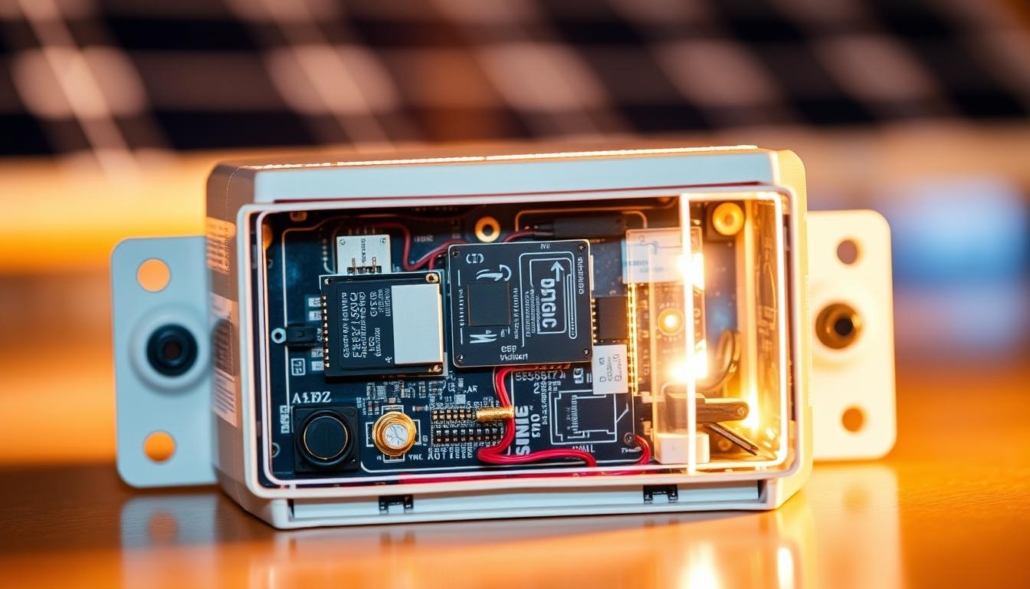

Key Components and Materials for Effective Lightning Protection

Superior materials form the backbone of reliable energy infrastructure safeguards. Every connection point and conductor plays a critical role in redirecting destructive forces away from sensitive electronics.

Conductor Selection and Rod Specifications

Copper wire remains the gold standard for grounding systems. Main connections demand 6 AWG or thicker strands, while secondary links require 10 AWG minimum. “You can’t cheat physics,” warns a Texas-based installer. “Undersized conductors become instant failure points during surge events.”

Lightning rods utilize 12-16mm round steel for optimal strike dissipation. Alternative configurations employ 8mm rods or 4mm flat metal strips. Hot-dip galvanized grounding rods (50mm diameter, 3.5mm walls) withstand decades of soil corrosion.

Surge Suppression Essentials

Quality protection devices combine speed and capacity. Residential setups need 300V DC/AC units with sub-25-nanosecond response times. Look for:

- 50kA+ energy absorption ratings

- Visual status indicators

- Weather-resistant casings

Unified Grounding Networks

Effective integration bonds all components through copper links. Down conductors require 8mm steel or 4mm² flat profiles. Certified clamps create permanent bonds between:

| Element | Specification |

|---|---|

| Inverter chassis | 6 AWG copper |

| Mounting racks | 4mm flat steel |

| Earth rods | 50mm galvanized pipe |

Regular resistance checks ensure grounding systems stay below 25 ohms. This multi-layered approach eliminates voltage gaps that endanger equipment during electrical storms.

Design Strategies and Layout Considerations

Effective energy setups require more than quality components—strategic spatial planning determines their survival during electrical storms. Positioning arrays within existing shielded zones prevents direct strikes while maximizing sunlight capture. This balance demands expertise in both electrical safety and renewable energy efficiency.

Optimizing Array and Component Placement

Shading analysis proves critical when integrating defensive structures. Rods or masts must deflect strikes without blocking peak-hour sunlight. A Texas-based installer notes: “We model sun paths across seasons to position safeguards where shadows fall on grass, not panels.”

IEC 62305-3 standards dictate minimum clearances between arrays and metallic building elements. These gaps prevent side-flashing—a phenomenon where surges jump between nearby conductors. Rooftop installations often face space constraints, requiring creative solutions:

| Design Factor | Challenge | Solution |

|---|---|---|

| Array Placement | Protection zone limits | 3D modeling software |

| Separation Distance | Structural interference | Copper bonding bridges |

| Shadow Management | Energy loss risks | Adjustable mast heights |

Soil conductivity and local storm patterns heavily influence layout decisions. Coastal Florida homes need different approaches than Arizona desert installations. Professionals assess six key elements:

- Building height relative to surroundings

- Historical lightning strike density

- Roof material conductivity

Equipotential bonding becomes essential when maintaining physical gaps isn’t feasible. This technique creates unified electrical potential across all metal components, eliminating dangerous voltage differences. Regular thermal scans verify bond integrity across seasons.

Grounding Techniques and Safety Best Practices

Effective energy infrastructure relies on robust connections to the planet’s natural charge. Proper earth bonding redirects destructive forces while maintaining equipment integrity. Three critical factors determine success: material quality, soil conditions, and maintenance rigor.

Fundamental Grounding Concepts and Soil Considerations

Soil type dramatically impacts performance. Sandy earth in Arizona requires 4x more rods than clay-rich Georgia soil to achieve 10-ohm resistance. Grounding systems in arid regions often use radial configurations with multiple 8-foot rods spaced 30 feet apart.

“You can’t fight physics – dry soil acts like insulation against proper energy dissipation,” notes a Nevada-based installer.

Connecting Multiple Components Safely

All metallic elements must bond to one central point. This prevents voltage gaps between equipment. Use 4 AWG copper for main links – thinner wires risk melting during surge events.

| Soil Type | Rod Quantity | Configuration |

|---|---|---|

| Clay | 2-3 | Vertical |

| Sand | 6-8 | Radial |

| Loam | 3-4 | Triangle |

Maintenance Tips for Lasting Protection

Test resistance annually using clamp meters. Replace corroded clamps immediately – oxidation increases resistance by 300%. Keep rods free from vegetation and check connections after extreme weather.

Professional assessments measure soil moisture changes across seasons. They adjust configurations to maintain under-10-ohm performance year-round. Don’t guess – test.

Troubleshooting Common Issues and System Updates

Energy installations often fail at connection points long before major components wear out. A Texas facility recently lost three inverters due to overlooked wiring gaps in their outdoor generator setup. Regular diagnostics catch 83% of these issues before they escalate.

Identifying and Resolving Wiring or Inverter Concerns

Check equipment after storms using thermal cameras to spot loose terminals. Most AC-side surges enter through detached ground wires near external power sources. Replace cracked insulation immediately—exposed conductors attract stray currents.

For Victron inverters, monitor error codes indicating charge controller stress. Low battery resistance accelerates wear during frequent cycling. Upgrade connections with marine-grade lugs if readings fluctuate more than 12% between checks.

Understanding When and How to Upgrade Your Protection System

Modern suppressors outperform decade-old models by 40% in response speed. Consider updates if your generator lacks integrated surge arrestors or shows carbon tracking on terminals. Layered defense becomes critical when expanding equipment capacity.

Replace entire wiring runs if multiple battery banks show inconsistent voltage levels. Professionals recommend biennial ground resistance tests and firmware updates for smart charge regulators. Don’t wait for failure—proactive care keeps systems operational through their planned service end.