Reliable Lightning Arresters for Residential & Commercial Use

A single lightning strike can unleash over 100 million volts – enough to power a small town for days. This raw energy threatens homes, businesses, and critical infrastructure every 10 seconds across the U.S. during storm season.

Specialized lightning protection systems act as silent guardians against these electrical onslaughts. They create controlled pathways for dangerous surges, diverting them safely into the ground before they reach sensitive equipment.

Modern solutions work seamlessly with existing power networks. From smart refrigerators to industrial transformers, these systems shield valuable assets without disrupting daily operations. Their automatic response requires zero human intervention.

Investing in robust safety measures prevents catastrophic damage. Property owners avoid costly repairs to fried electronics, structural fires, and potential liability issues. The technology pays for itself through avoided disasters.

Understanding how these devices function helps homeowners and facility managers make smarter choices. Proper installation ensures continuous defense against nature’s most unpredictable power surges while maintaining energy efficiency.

Understanding Lightning Arresters and Their Role

Electrical systems face unseen threats from sudden voltage spikes. Specialized protective devices manage these risks by redirecting dangerous energy away from critical infrastructure. This section explains their core functions and operational mechanics.

What Is This Protective Device?

Often called surge diverters, these safety tools connect to power lines and structural wiring. They contain advanced materials like zinc oxide that respond instantly to voltage changes. When surges occur, internal components create low-resistance paths to ground, shielding connected equipment.

Surge Defense Mechanisms

These systems operate like emergency exits for excess electricity. During normal conditions, they remain inactive. When voltage exceeds safe levels, semiconducting elements activate within nanoseconds. This rapid response channels harmful currents into the earth, preventing damage to appliances and electrical networks.

| Feature | Surge Diverters | Traditional Rods |

|---|---|---|

| Primary Function | Redirects incoming surges | Attracts direct strikes |

| Installation Point | Power lines & equipment | Building rooftops |

| Response Time | Nanoseconds | Instantaneous |

| Protection Scope | Entire electrical system | Structural framework |

Modern versions integrate with existing grounding systems, offering multi-layered defense. Their automatic operation ensures continuous protection without manual intervention, making them essential for both residential and commercial applications.

Evaluating the Types and Features of Lightning Arresters

Protective systems vary significantly in design and capability. Understanding technical specifications ensures optimal performance across residential grids and industrial complexes.

Key Characteristics: Spark-Over Voltage and Durability

Spark-over voltage determines when a device activates. It must stay above standard operating levels but below equipment damage thresholds. Modern units achieve this balance through precision engineering.

Durability matters for long-term reliability. High-quality models withstand thousands of surge events without performance loss. Porcelain housings with safety vents prevent explosions during extreme discharges.

Material Insights: Silicon Carbide and Zinc Oxide Performance

Silicon carbide composites, like GE’s historic Thyrite, revolutionized surge protection. These materials provide adjustable resistance during electrical disturbances. However, they require series gaps for optimal operation.

Zinc oxide dominates modern applications. Its non-linear resistance allows faster response times and better surge absorption. Substation-grade units stack metal oxide discs in robust cylinders, outperforming older technologies.

| Material | Response Time | Surge Capacity |

|---|---|---|

| Silicon Carbide | Microseconds | 50kA |

| Zinc Oxide | Nanoseconds | 100kA+ |

Selecting the Right Lightning Arresters for Residential & Commercial Use

Choosing appropriate surge defense equipment requires understanding both infrastructure needs and environmental risks. Incorrect device classification ranks among the top causes of preventable electrical system failures during storms.

Assessing Your Electrical System’s Requirements

Start by evaluating your power supply characteristics. Residential setups typically use single-phase systems, while commercial buildings require three-phase configurations. Voltage thresholds determine whether Class 1 or Class 2 units become necessary.

Load capacity analysis prevents underpowered solutions. High-energy facilities like data centers need arresters handling 100kA surges, whereas home systems often function safely with 50kA ratings. Always account for future appliance upgrades during this assessment.

Matching Device Class to Operational Demands

Class 1 units defend against direct strikes near power entry points. These heavy-duty models divert up to 200kA surges safely. Class 2 devices protect internal circuits but fail catastrophically when used as primary defense layers.

| Class | Surge Capacity | Installation Point |

|---|---|---|

| 1 | 100-200kA | Main service panels |

| 2 | 50-100kA | Subpanels/appliances |

Modern electrical panels integrate compact arresters seamlessly. These space-saving designs provide whole-house protection without complex rewiring. For commercial applications, layered systems combine multiple device classes at different power distribution stages.

Professional evaluations prevent catastrophic damage from mismatched equipment. Certified technicians verify grounding quality, voltage compatibility, and physical space constraints during installation planning.

Installation Essentials: Proper Placement and Professional Guidance

Strategic positioning forms the backbone of effective surge defense systems. Proper setup determines whether protective devices function as intended or become expensive decorations.

Ideal Locations for Installation in Homes and Buildings

Residential systems demand focus on the main electrical panel. This central hub intercepts surges before they reach appliances. Installers typically place devices within 18 inches of the panel for optimal protection.

Commercial facilities require multi-point defense. Critical spots include power line entry points, transformer junctions, and server rooms. Industrial sites often add secondary units near heavy machinery and data centers.

Ensuring Compliance with Safety Standards and Codes

Certified electricians verify three non-negotiable elements: ground resistance below 25 ohms, proper bonding between metal components, and NEC-compliant clearances. These measures prevent dangerous side flashes during major surges.

Local building codes often mandate specific mounting heights and weatherproof enclosures. Professionals use torque wrenches to ensure secure connections and corrosion-resistant materials for outdoor installations. Regular inspections maintain system integrity over decades of use.

| Installation Factor | Residential | Commercial |

|---|---|---|

| Primary Location | Main service panel | Power entry points |

| Ground Resistance | <25 ohms | <5 ohms |

| Inspection Frequency | Biennial | Annual |

Lightning arresters: Key Considerations for System Integration

Modern electrical defenses require coordinated strategies that combine multiple technologies. Effective protection demands seamless interaction between surge diverters, structural safeguards, and energy management systems.

Integrating with Surge Protection and Grounding Systems

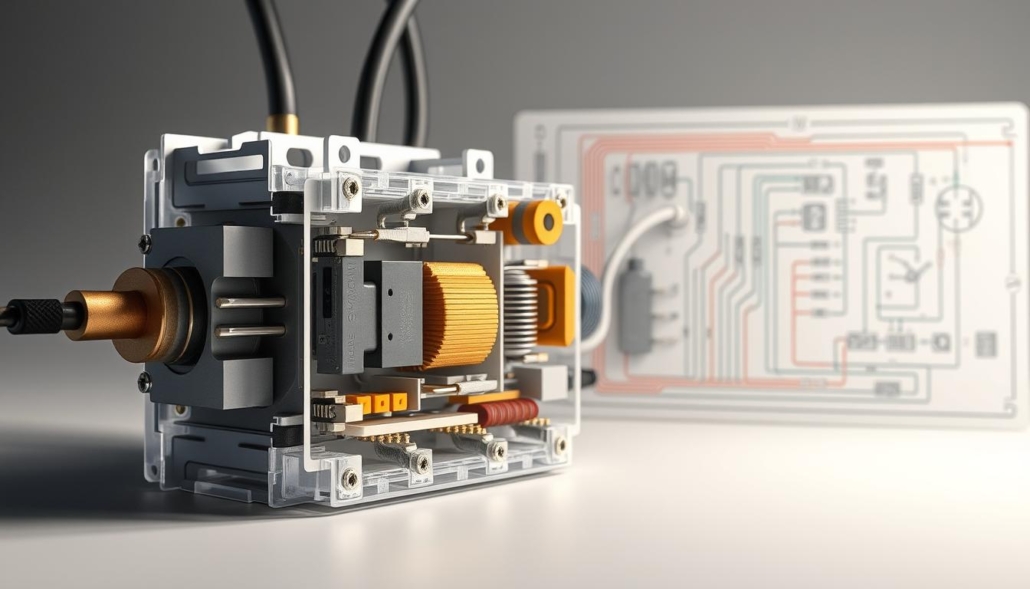

Multi-layered defense systems pair surge diverters with lightning rods and grounding networks. Rods intercept direct strikes, while protective devices manage induced surges in wiring. Proper bonding ensures all components share a common earth connection.

Coordination between series inductors and surge suppressors prevents voltage conflicts. This teamwork filters high-frequency transients before they reach sensitive electronics. Commercial facilities often install cascading protection layers at power entry points and critical equipment junctions.

Long-Term Reliability and Maintenance Strategies

Durable systems require scheduled inspections and performance testing. Technicians check connection tightness, housing integrity, and grounding resistance every 12-24 months. Advanced models feature self-monitoring chips that track surge events and component wear.

Replacement protocols prioritize aged units showing corrosion or reduced conductivity. Many industrial sites implement phased upgrades, maintaining protection during equipment swaps. Proper care extends device lifespans by 40-60% compared to neglected systems.

| Integration Factor | Residential | Commercial |

|---|---|---|

| Surge Coordination | Single-tier protection | Multi-stage defense |

| Grounding Network | Copper rod system | Grid-type configuration |

| Maintenance Cycle | 24 months | 6-12 months |

| Monitoring | Visual checks | Automated alerts |

Proactive maintenance programs reduce repair costs by 78% according to industry studies. They combine thermal imaging scans with resistance tests to catch issues before failures occur. This approach keeps electrical energy systems protected through decades of service.

Conclusion

Modern properties demand robust defense mechanisms against nature’s electrical threats. Advanced surge protection devices serve as silent sentinels, diverting dangerous energy away from critical infrastructure before it causes irreversible damage.

Professional installation proves vital for system effectiveness. Certified technicians verify ground connections, voltage thresholds, and compliance with local safety codes. Their expertise ensures proper integration with existing power networks and structural safeguards like lightning rods.

Strategic investments in quality protection yield long-term benefits. They prevent costly equipment replacements, data loss, and potential fire hazards. Regular maintenance by qualified electricians extends device lifespans while maintaining peak performance.

Understanding these systems empowers smarter safety decisions. Combining surge diverters with comprehensive protection strategies creates a layered defense against unpredictable events. This approach safeguards both residential comfort and commercial operations, delivering lasting peace of mind.