How Much Does a Lightning Protection System Cost?

Every year, 40 million lightning strikes hit U.S. soil. While many view these events as rare threats, recent data reveals a shocking truth: electrical storms cause $1 billion in annual homeowner insurance claims. State Farm reports an average claim of $18,000 per incident – enough to bankrupt unprepared families.

Modern structures face hidden vulnerabilities. Commercial properties suffer over $100 million in direct fire damage yearly from strikes. Yet less than 15% of buildings have proper safeguards. This gap leaves roofs, electronics, and lives at risk when storms ignite.

Installing specialized safeguards transforms this equation. Certified solutions don’t just deflect strikes – they shield investments while lowering insurance premiums. Costs vary based on square footage, materials, and regional weather patterns. For example, a 2,500 sq ft home typically requires different components than a manufacturing plant.

Key Takeaways

- Electrical storms cause $18,000+ in average residential damage per incident

- Professional installation ensures compliance with NFPA safety standards

- System expenses depend on structure size and local climate risks

- Insurance discounts often offset 20-35% of upfront costs

- Unprotected buildings face 7x higher fire risks during thunderstorms

Expert teams analyze your unique needs through site evaluations and risk assessments. Call (813) 630-2757 for tailored solutions that balance budget and safety. Don’t wait for disaster – proactive measures today prevent financial shocks tomorrow.

Overview of Lightning Protection Systems

Nature’s most powerful electrical events carry enough energy to vaporize steel. Lightning strikes superheat air to 60,000°F – five times hotter than the sun’s surface. These forces trigger devastating consequences, from melted wiring to explosive structural failures.

Understanding the Purpose and Benefits

Engineered safeguards intercept strikes through three critical elements: air terminals, conductors, and grounding networks. This triad creates a safe path for electrical currents, diverting them away from vulnerable materials. Proper installation reduces fire risks by 87% compared to buildings without protection.

Key advantages include:

- Prevention of electrical surges in appliances and HVAC systems

- Compliance with NFPA 780 safety standards

- 20-35% reductions in property insurance premiums

Lightning Strikes and the Cost of Damage

Recent data reveals stark contrasts in regional vulnerability:

| Region | Annual Strikes | Average Claim | Risk Level |

|---|---|---|---|

| Florida | 1.4 million | $28,400 | Extreme |

| Gulf Coast | 950,000 | $19,800 | High |

| Pacific States | 62,000 | $9,200 | Moderate |

“Uncontrolled electrical surges can ignite fires in under 0.3 seconds. Protection systems buy critical time for evacuation and emergency response.”

Business interruptions compound repair costs, with 43% of affected companies reporting revenue losses exceeding $150,000. Contact our experts at (813) 630-2757 to assess your property’s unique risks and implement cost-effective safeguards.

How much does lightning protection system cost? – In-Depth Cost Analysis

Property safeguards against electrical storms require strategic budgeting. ECLE’s nationwide study reveals price differences across structure types and materials. These variations stem from safety requirements, regional factors, and construction timelines.

Residential vs. Commercial Price Ranges

Single-family homes typically spend $2,000-$4,000 for complete safeguards. This covers standard components like rods and grounding networks. Commercial buildings often start at $10,000, with prices climbing for complex layouts or tall structures.

| Structure Type | Average Price Range | Key Factors | Material Impact |

|---|---|---|---|

| Residential | $2,000 – $4,000 | Roof size, soil type | 15-20% variance |

| Commercial | $10,000+ | Height, equipment density | 25-40% variance |

Material Choices and Workforce Expenses

Copper conductors cost 30% more than aluminum but last decades longer. Labor accounts for nearly half of total expenses in retrofit projects. New constructions save 18-22% by integrating safeguards during initial wiring.

Regional differences dramatically affect budgets. Rocky soil areas need deeper grounding, adding $500-$1,200. Coastal zones often require corrosion-resistant materials, increasing system costs by 12-15%.

“Choosing certified installers ensures compliance with NFPA standards while maximizing insurance discounts.”

For precise quotes tailored to your building, contact our specialists at (813) 630-2757. We evaluate architectural features and local risks to optimize your investment.

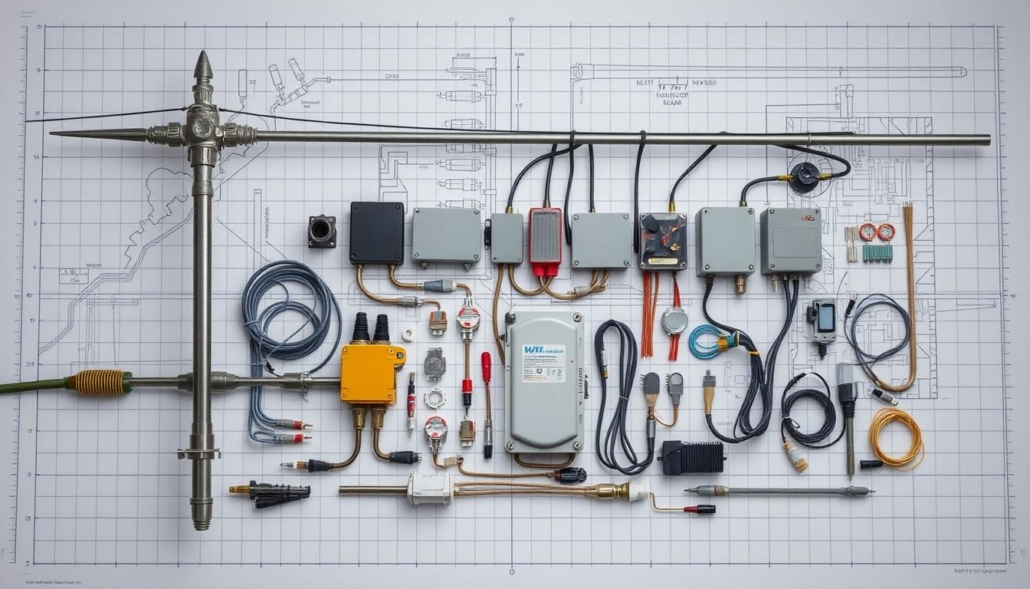

Key Components and Installation Factors

Three critical elements form the backbone of effective electrical surge defense. Proper integration of these components requires precision engineering and certified expertise.

Air Terminals, Conductors, and Grounding Systems

Air terminals (commonly called lightning rods) range from $50-$300 per unit based on material. Copper models outperform aluminum in longevity but increase initial costs. These strike receptors mount on roof peaks and high points to intercept discharges.

Professional installation creates continuous pathways using:

- Vertical conductors along walls and chimneys

- Horizontal bonding networks across roof surfaces

- Interconnected grounding rods spaced 20 feet apart

Grounding systems require multiple 10-foot copper-clad rods driven into moist soil. Rocky terrain may need specialized augers, adding $800-$1,200 to project costs.

Compliance with Safety and Certification Standards

All components must meet UL Solutions and Lightning Protection Institute specifications. Non-compliant installations void warranties and insurance benefits.

“Proper grounding separates functional systems from catastrophic failures. One undersized rod can compromise an entire building.”

Certified technicians follow NFPA 780 guidelines for:

- Surge protector placement near electrical panels

- Conductor spacing (every 20 feet on roof edges)

- Soil resistivity testing before grounding

Our specialists at (813) 630-2757 verify compliance through third-party inspections. This ensures eligibility for insurance discounts up to 35% in high-risk regions.

Regional Influences and Buyer’s Guide Tips

Geography shapes lightning defense strategies more than most property owners realize. Coastal plains demand different solutions than mountain valleys, while urban electrical grids face unique challenges compared to rural installations.

Impact of Regional Trade Practices and Soil Conditions

Soil composition dictates grounding expenses. Rocky Appalachian terrains require specialized drilling equipment, adding $800-$1,500 to projects. Sandy Florida soils need deeper rod placements to maintain conductivity.

| Region | Grounding Challenges | Cost Impact |

|---|---|---|

| Gulf Coast | High salinity corrosion | +18% material costs |

| Rocky Mountains | Bedrock penetration | +22% labor costs |

| Midwest | Clay soil resistivity | +12% testing fees |

Urban installations in New York or Chicago cost 25% more than rural projects due to union wage rates and permit requirements. East Coast Lightning Equipment data shows retrofit work in Boston averages $4,200 versus $3,100 in rural Maine.

Selecting Certified Installers and Quality Materials

Always verify Lightning Protection Institute (LPI) certification and UL Solutions approval. These credentials ensure compliance with NFPA 780 standards for conductor spacing and surge protector placement.

“Copper outperforms aluminum in coastal regions but adds 30% to material budgets. We match conductors to local climate threats.”

New construction projects save 19-24% by integrating protection during framing. Retrofits require creative routing around existing structures, resulting in a 40% increase in labor hours.

Contact Information: Call Us (813) 630-2757 for Expert Advice

Our specialists analyze soil reports, regional strike patterns, and building codes to optimize your project. Call (813) 630-2757 for tailored solutions that address local risks while maximizing insurance discounts.

Conclusion

Protecting properties from nature’s electrical fury demands smart investments. Certified lightning protection systems prevent catastrophic damage at a fraction of repair costs. Insurance providers recognize this value, offering premium reductions up to 35% for safeguarded buildings.

Professional installation proves critical. Certified specialists design defenses tailored to regional risks – from coastal corrosion to challenges posed by rocky soil. Their expertise ensures compliance with NFPA standards while maximizing long-term savings.

The true expense lies in inaction. One severe strike can devastate structures lacking proper grounding networks. Proactive measures deliver decades of protection, preserving both property value and peace of mind.

For customized solutions meeting your location’s unique threats, contact our LPI-certified team at (813) 630-2757. We optimize every component – from air terminals to surge suppressors – creating resilient defenses against nature’s unpredictable power.